-

Pre-forging Heating - Induction Heating

High efficiency, energy saving, wide adaptability

Handling workpieces: bars, square steel, pipes, plates, profiles, special-shaped workpieces,

Carbon steel stainless steel,etc

Features: Variable load adaptive, 0.2-20KHZ Frequency conversion adaptive;Direct fast start,

temperature automatic replenishment;Compensation technology to achieve fast temperature;

Temperature closed-loop control (power supply participates in automatic power control);Customized process selection system

-

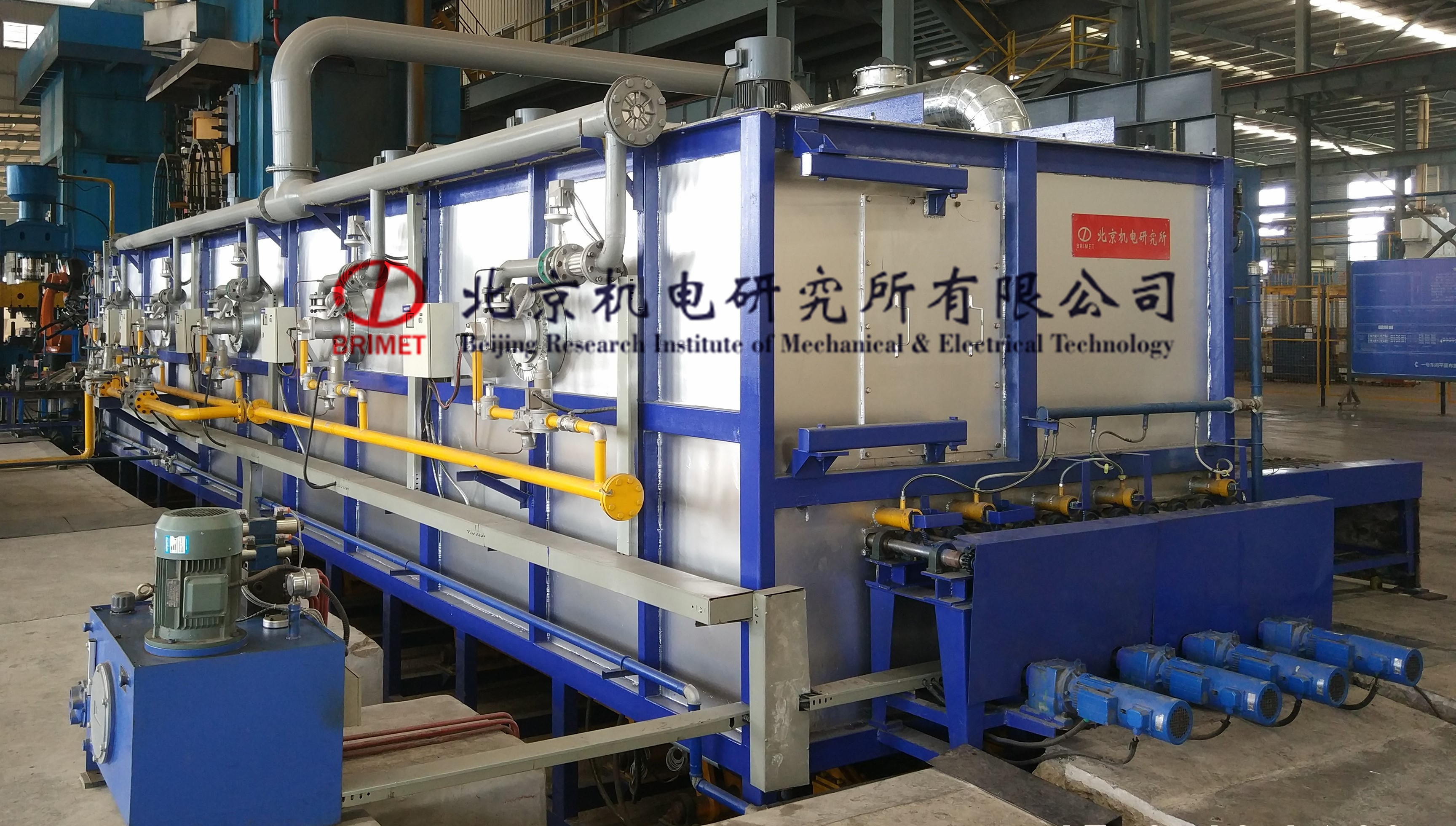

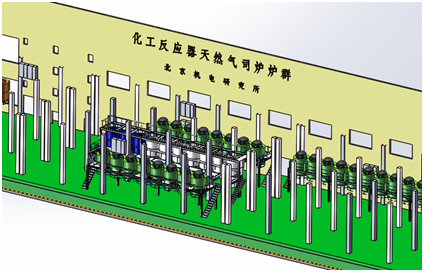

Pre-forging Heating - gas heating

Energy saving, wide adaptability

Heating range: heating before forging

Combustion system: regenerative burner, overall heat storage; Self-warming burner

Regenerative type: low temperature and high temperature dual mode control

-

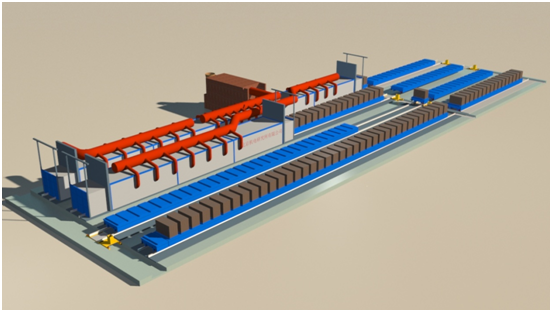

The production Line of High-strength Plate, Armor Plate, Wear Plate without Deformation to Strengthen

Precision shape control technology

Annual processing capacity: 1.5-20,000 tons per year.

Handling pieces: 2-4mm, 4-12mm and 12mm or more multi-specification series production lines

Roller bottom production line, chamber type, stepper production line, etc

Purpose:Used in national defense industry, engineering machinery, automobile and other industries

-

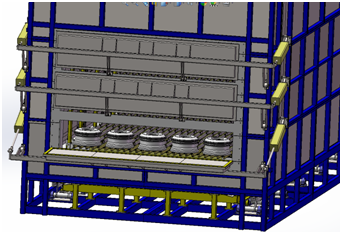

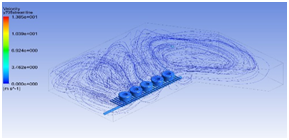

Protective Atmosphere Ultra-high strength Plate Press Hardening Production Line

Integrated forming and quenching, high degree of automation, and customized strength can be realized

Processing capacity: thickness 1-3mm× width 265-2000mm× length 2500m, output 1 million punches/year

Protective atmosphere ceramic roller furnace (multi-layer chamber furnace, drawer furnace), servo press, etc

Purpose:Used in automotive and other industrie

-

Track Shoes Heat Treatment Line (spray quenching line, press quenching line, high-precision tempering line)

Processing capacity: annual output of 100,000-150,000 pieces

Quenching method: spray quenching, pressure quenching and dip quenching

Purpose:Used in military, engineering machinery and other industries

-

Arc Cutting Edge Press Quenching Heat Treatment Line

Asia's first, pulse pressure quenching patent technology has little deformation

Processing capacity: annual output of 1.5-20,000 tons, many specifications, large output, high efficiency

Purpose:Used in construction machinery, tools, composite materials and other industries

-

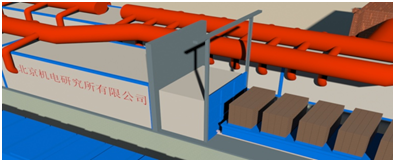

Coal Machine Scraper Production Line

Structural form: pusher type stepping type

Features: high efficiency of heat utilization after forging, low energy consumption, small deformation, uniform hardness, mechanical discharge quenching

-

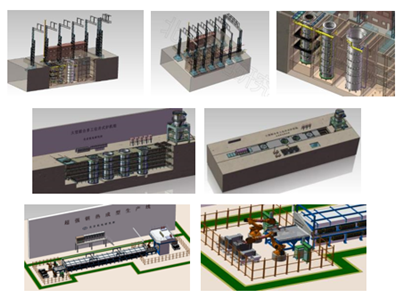

Large deep-well Furnace Complex Set

Patented products

Structural form: equal diameter, variable cross-section

Equipment assembly: pit furnace, quenching system, circulation system, platform

Size specification: multi-specification, deep up to 35m

-

Bottom Pit Furnace, Variable Section Pit Furnace

Structural form: seat bottom support top hood structure

Equipment assembly: pit furnace, quenching system, circulation system, platform

Size specification: multi-specification, deep up to 35m. Working capacity: large nuclear power

rotor and other long shaft parts single furnace 350t

Product performance: precise temperature control (±3 °C), reasonable cooling

-

Opening-close Heat Treatment Equipment

Structural form: two halves rotate and split, workpiece vertical heating, seat bottom support, top support

Working capacity: large nuclear power rotor and other long shaft parts, single furnace 350t

Size: multi-specification, height 22m

-

Controlled Atmosphere Well Furnace Line

Structural form: bottom support, furnace hanging

Working capacity: up to 11m deep, 2.5m diameter

Size: Multi-specification

-

Joint Unit

Technical features: full protective atmosphere heating and quenching, less workpiece without deformation, multi-station automatic operation

Working capacity: processing workpiece diameter 3.5m length 13m

Workpiece performance: uniform performance after quenching and tempering treatment, small deformation

-

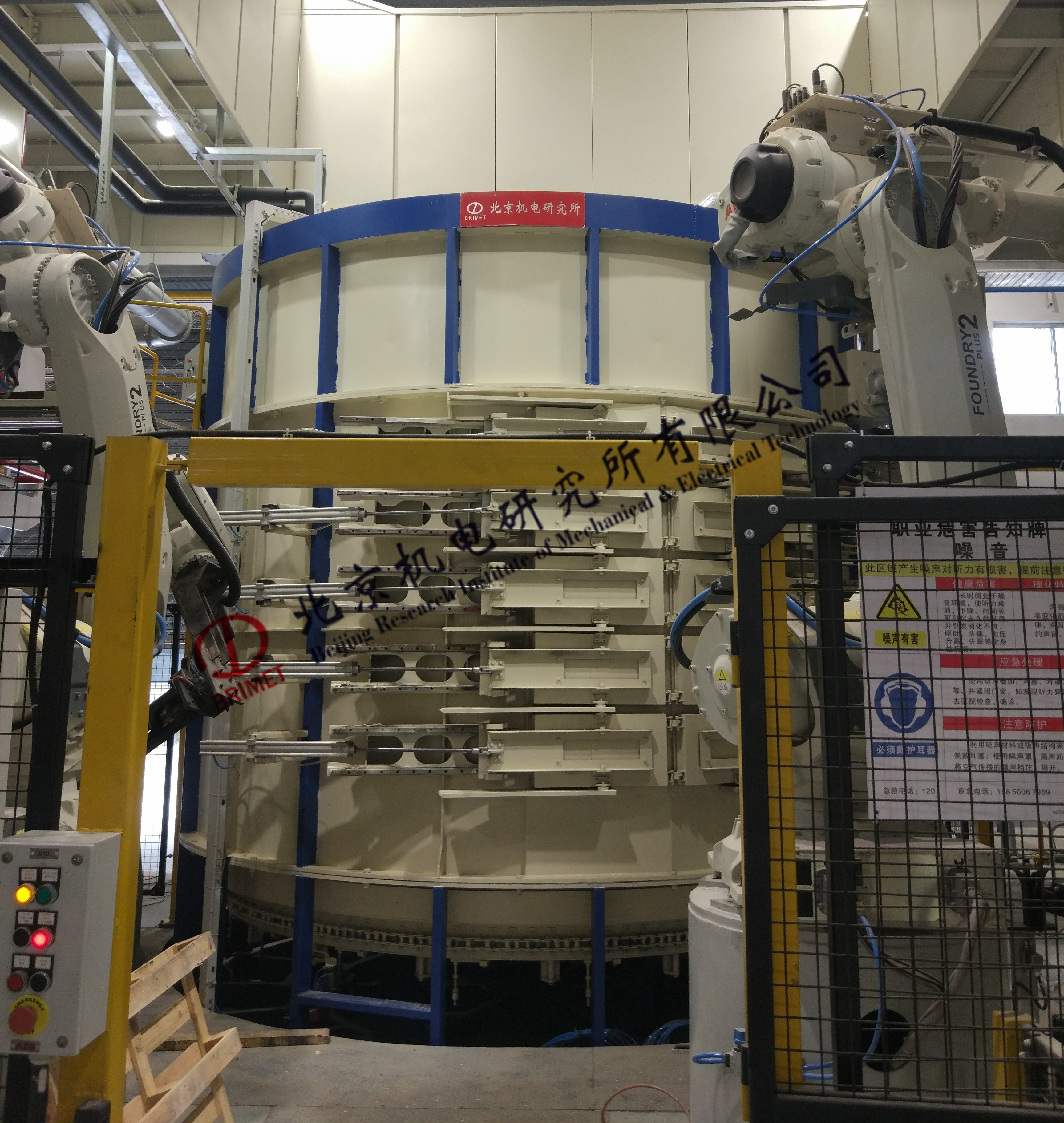

Multi-station Rotary Heating Pit Furnace

Structural form: workpiece rotation, revolution

Features: High precision heating

Size: Multi-specification

-

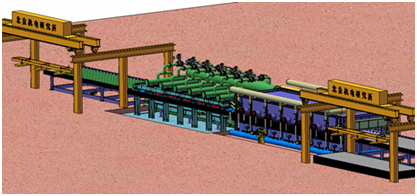

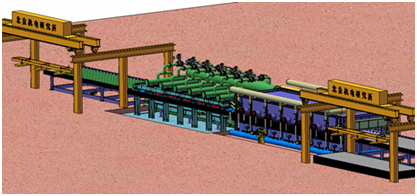

Bar Quenching and Tempering Heat Treatment Line

Patented technology, compound heating, less deformation

Structural form: combustible heating or induction preheating, gas or electric heating and heating

Working capacity: annual output of 1~30,000 tons

Workpiece performance: uniform performance after quenching and tempering treatment, small deformation

-

Automotive Rack Rod Conditioning and Tempering Heat Treatment Production Line

Patented technology

Structural form: roller bottom type, spiral push type

Working capacity: annual output of 1.5-20,000 tons

Workpiece performance: after treatment, the hardness difference of the workpiece core table is 2-3HRC, and the straightness does not exceed 1mm/m. It has the characteristics of large output, Features: High Efficiency and Small Deformation

-

Pumping Rod Heat Treatment Production Line

Structural form: tunnel type

Working capacity: annual output of 4 million meters

Workpiece performance: the characteristics of large output

Features: high efficiency and small deformation of the workpiece after processing

-

Heat Treatment Line for Finished Rolled Rebar

Structural form: induction heating

Working capacity: annual output of 1.5-20,000 tons

Workpiece performance: large output, high efficiency, small deformation characteristics

-

Drill Pipe Weld Heat Treatment Production Line

Structural form: induction heating

Workpiece performance: high efficiency, small deformation characteristics, meet API standards

-

Automobile Front Axle Crankshaft Quenching and Tempering Heat Treatment Production Line

Structural form: hanging type, pusher type; Directional cooling technology

Workpiece performance: high efficiency, small deformation characteristics

-

Connecting Rod, Crankshaft Non-aligned Steel Control Cooling Heat Treatment Line

Structural form: hanging type, pusher type, chain plate type

Workpiece performance: high efficiency, small deformation characteristics

-

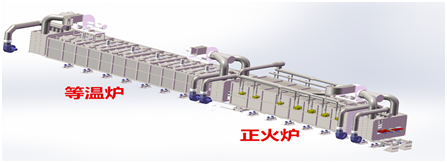

Bearing Steel Isothermal Spheroidized Annealing Continuous Line

Structural form: roller bottom continuous, push plate type isothermal spheroidization, vacuum gas locking, etc

Workpiece performance: less oxidation, large output, high efficiency, small deformation characteristics

-

Normalized Isothermal Continuous Line

Structural form: step-by-step type, push plate type, roller-bottom continuous isothermal normalizing, etc

Working capacity: hourly output multi-specification

Workpiece performance: precise temperature control, controllable cooling, uniform performance

-

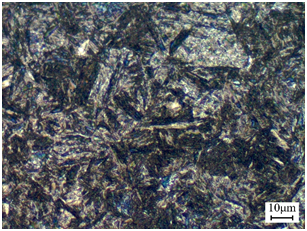

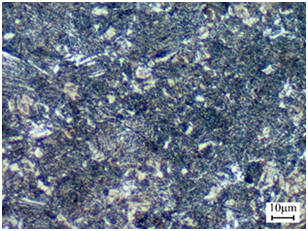

Roll dual-frequency Quenching Process and Complete Set of Equipment

Structural form: preheating, roll quenching, roll diameter quenching, tempering, cryogenic

Technical features: dual-frequency variable frequency induction heating, closed-loop control, good process stability and reproducibility

Workpiece performance: the surface hardness of the roll, the depth of the hardened layer, the metallographic structure and flaw detection have reached the national standard

-

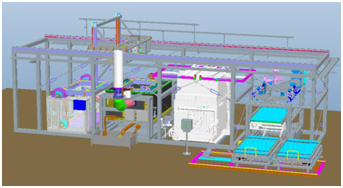

Automatic heat treatment line (sealed box type)

Technical features: high degree of automation, simple operation, high production efficiency and safe use

Equipment composition: box-type multi-purpose furnace, cleaning machine, tempering furnace, mobile material truck, fixed material table, movable material table, material tray

Working capacity: multi-specification

-

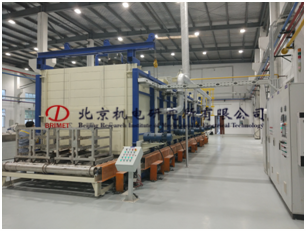

Heat Treatment Automatic Line (chamber type)

Technical features: wide range of workpiece adaptation, multi-station automatic operation, stable workpiece performance

Equipment composition: trolley furnace, chamber furnace, quenching oil tank, quenching water tank, manipulator, etc

Working capacity: multi-specification workpiece

-

Automatic Heat Treatment Line (trolley furnace)

Technical features: precise control of heating speed, heat preservation effect and cooling speed

Heating range: quenching heating, annealing heating, tempering heating

Combustion system: regenerative burner, self-preheating burner, high-speed burner